In 2024, global light vehicle sales stayed resilient at 89 million units, while the windshield wiper market operated as a USD 3.9 billion industry with steady long-term growth (CAGR ~1.4%).

Yet beneath stable demand lies unstable fitment truth: vehicle platforms are shared globally, but configurations, regional interfaces, and catalog updates are not.

This year, our conversations with distributors from Canada to Dubai revealed a new procurement mantra:

“We’re not buying wipers. We’re buying the certainty that they install right the first time.”

Forecasting and vehicle registration tools (e.g., S&P Global Mobility) cover more than 97% of countries, powering global platform-level insights.

But parts catalog data for aftermarket components still comes from multiple regional sources — often producing different results for the same vehicle.

A Southeast Asian importer once showed us their system:

“The same Japanese SUV exists under 4 wiper part numbers. Different sizes. Different interfaces. Same car. We spend more time managing data than moving product.”

Common friction points include:

To explain the financial impact, we rely on the industry-standard inventory metric:

Inventory Turnover (ITO) = Cost of Goods Sold / Average Inventory

In cross-border procurement, businesses frequently build buffer stock for fitment uncertainty, fragmenting SKUs across regional hubs and depressing turnover performance.

For a million-dollar-scale annual wiper procurement line, this can translate into:

Fitment mistakes in global operations trigger a chain of expensive inefficiencies:

One European service director summarized it best:

“Our technicians don’t fear complexity. They fear that every country defines complexity differently.”

From shop floors in Germany to quick-service chains in the U.S., we observed a shared pattern:

Important clarification for readers:

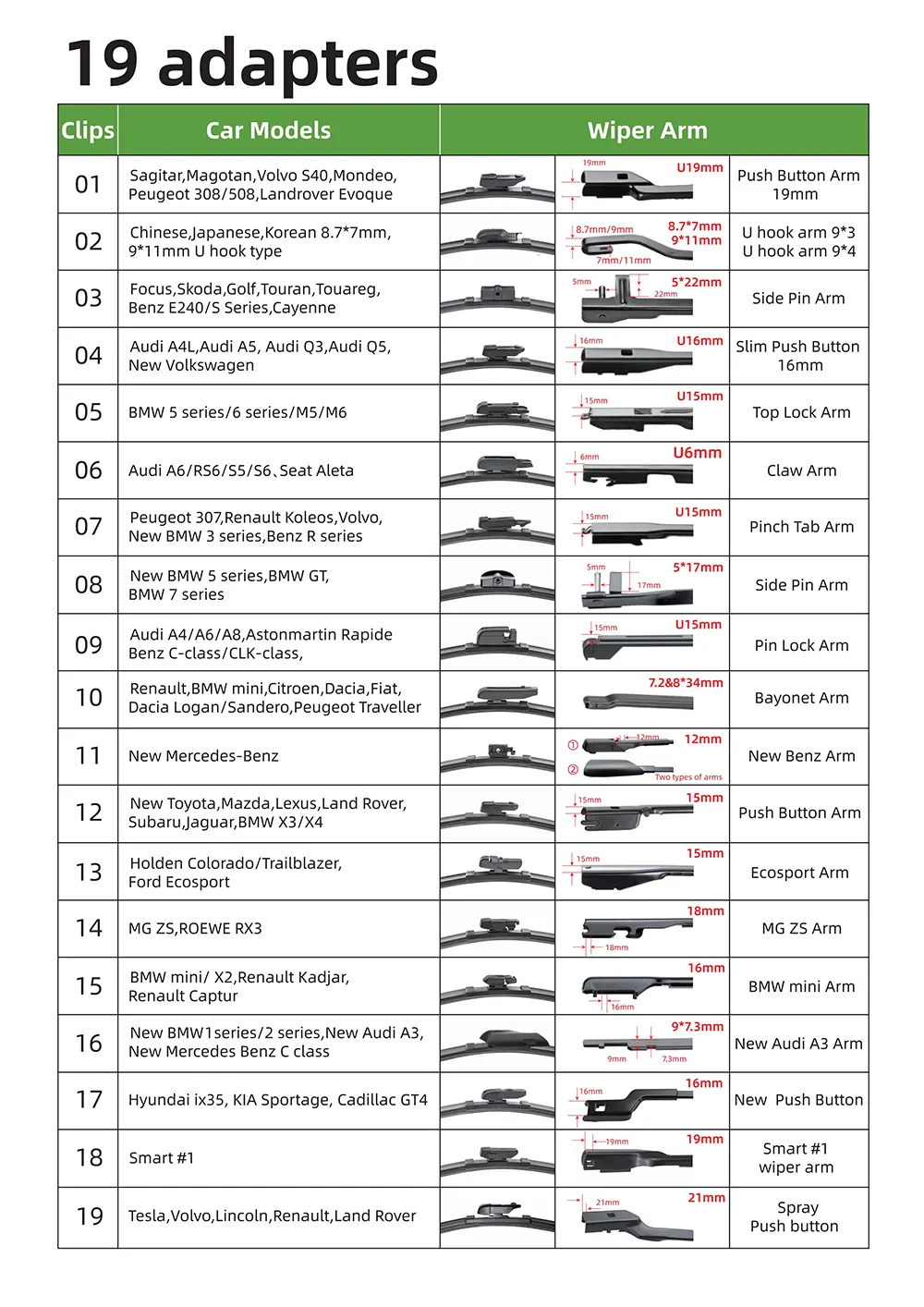

The 19 wiper arm adapter system mentioned here is our factory’s own R&D outcome, validated through 15,000+ real vehicle interface install tests over 18 months — not a universal industry statistic.

Our design philosophy borrowed from OEM platform strategy:

Reduce physical interface variants first. Standardize catalog logic second.

Our 19-adapter system integrates:

Procurement teams now share four core expectations globally:

Their supply chain director told us:

“One Dubai warehouse now serves 22 countries. We stopped localizing interfaces and started globalizing efficiency.”

The strongest B2B suwer SKUs with higher install certainty.

We provide a Global Fitment Efficiency Report to quantify SKU consolidation impact for multi-market procurement lines.

In a world of exploding vehicle configurations, simplification — when validated by engineering — becomes the ultimate scale advantage.

Transform Your Wiper Procurement from a Cost Center to a Efficiency Advantage.

To receive a customized Global Fitment Efficiency Analysis that quantifies the potential SKU reduction and cost savings for your operations, or to speak directly with our strategic procurement team:

Contact us at: wiperblade8@xmyujin.com

Let us provide you with data-driven insights tailored to your business.

-